Manufacturing Facilities

Bhosari Plant

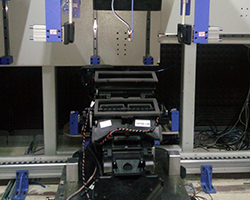

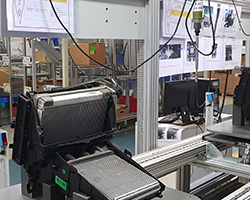

HVAC Line

- We have a Converyorised Assembly Line

- Fully Automated End Of Line Tester with Noise check

- The Assembly line Adopted IOT 4.0

- Support with easy access from AITS for design and manufacturing

- Expertise on implementation of VA/VE programs

- High performance low thickness heat exchangers used

- Low weight HVAC developed in India for B car segment

- Optimized Thermal management and Vehicle integration with the integration of R&D Team of AITTR and TTR under one roof

- Innovation drive across levels to provide latest technology products to OEM’s globally

Moshi Plant

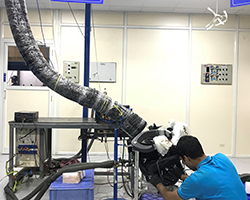

BTMS Line

- Torque control and interlocking in every stations.

- Pick up sensor for Gasket , sleeve and washer.

- EOLT is designed to test functioning of below parts:-

- LV wire harness

- HV Wire harness

- ECU, pump and Controller.

- Performance of condenser ,compressor …AC cycle.

- Coolant circulation with temp control mechanism

- Leak testing of Coolant cycle.

- Gas charging machine capable of vacuuming ,leak testing and charging the system.

- Capacity/shift:- 30 no

- Capacity/mth:- 1560 no

Moshi Plant

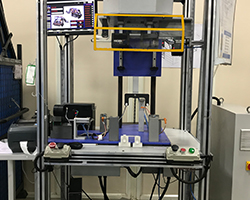

Roof HVAC Assembly Line

- Torque control in every stations.

- Nitrogen Hold testing for Leak test

- EOLT is designed to test functioning of below parts:-

- LV wire harness

- HV Wire harness

- ECU, Blower and Controller.

- Performance of condenser ,compressor AC cycle.

- Air velocity and temperature

- Each station quality control with rout card

- Gas charging machine capable of vacuuming ,leak testing and charging the system.

- Capacity/shift:- 8 no

- Capacity/mth:- 416 no